Certify

Certification planning and compliance verification

Meeting regulatory requirements for a new design requires a robust plan to show compliance with the relevant design standards. Certification planning is a key project phase conducted at the beginning of a design project to establish both the regulations to be complied with and the means by which compliance is to be shown.

In concert with the Programme Plan and Safety Plan (if warranted), the Project-Specific Certification Plan (PSCP) is a key document that provides a known roadmap for the design team, the verification team and the Regulator to follow in verifying the design meets all applicable regulatory requirements and dealing efficiently with any issues that inevitably arise during the programme.

A credible and concise product certification process ensures both safe-aircraft and effective commercial outcomes by:

- Timely, efficient and predictable product type design and production approvals;

- Clearly defined and understood roles, responsibilities, and accountability of all stakeholders;

- Timely identification of the certification basis, means of compliance, potential safety issues and business practice requirements;

- Effective issue resolution process that includes a pre-defined structured escalation to appropriate leadership within the Regulator and Applicant stakeholders;

- Optimal delegation using a risk-based approach with appropriate controls and systematic oversight; and

- Maximum use of the Applicant’s showing of compliance based on observed competencies.

A comprehensive PSCP developed at the beginning of a project makes the down-stream compliance demonstration and verification progress visible to all project stakeholders.

Innovaero in concert with CASA and the FAA have evolved a concise-but-comprehensive form of PSCP that meets the needs of all parties and happily work across jurisdictions.

Compliance demonstration by way of testing can occur in many forms. Some worth mentioning routinely used by Innovaero comprise structural testing, burn testing and flight testing.

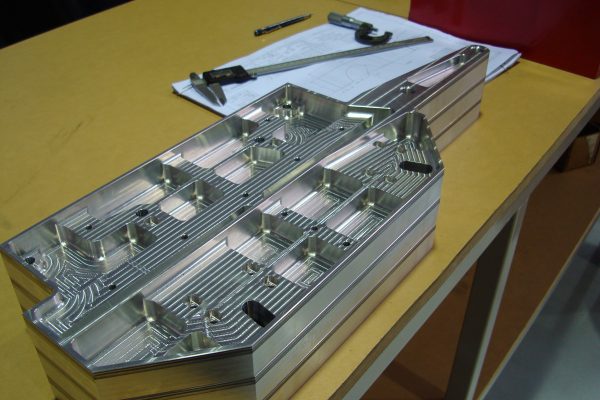

Structural testing

Structural testing can occur at a number of levels:

- Coupon testing of material samples to establish design allowable data, particularly useful for polymer materials and composite laminate design;

- Component testing for strength and/or stiffness verification;

- System or installation testing for all-of-system design verification; and

- In-process manufacturing verification for production parts.

Innovaero has all the necessary equipment and experience in coupon testing and system testing for both design certification and manufacturing process control.

Burn testing

Flammability of products in the cabin interior is a safety critical issue. For role equipment this can be a challenging issue when using COTS items or non-traditional aircraft materials in the cabin interior and establishing compliance with flammability requirements.

For many materials this also requires pre-conditioning in an environmental chamber to ensure the humidity is sufficiently low prior to the test occurring.

Innovaero has both environmental conditioning equipment providing a controlled atmosphere with humidity anywhere in the range of 5% through 95% and temperature from -50C through to 150C. These conditioned samples can then be tested in-house in a vertical burn test configuration. This is a useful design development tool as well as providing certification compliance evidence.

Flight testing

At some point a significant modification needs to be installed to an aircraft for flight testing. Innovaero has a comprehensive flight test capability and an impressive instrumentation package. A typical flight test aircraft will have not only air-data recorded (altitude, attitude, temperature and velocity) but also engine parameters (fuel flow, temperature, manifold pressure) and flight control data (control surface position and control forces).

Comprehensive flight test planning is performed early in the project to determine aircraft configurations and compliance objectives to be achieved as outlined in the PSCP.